| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

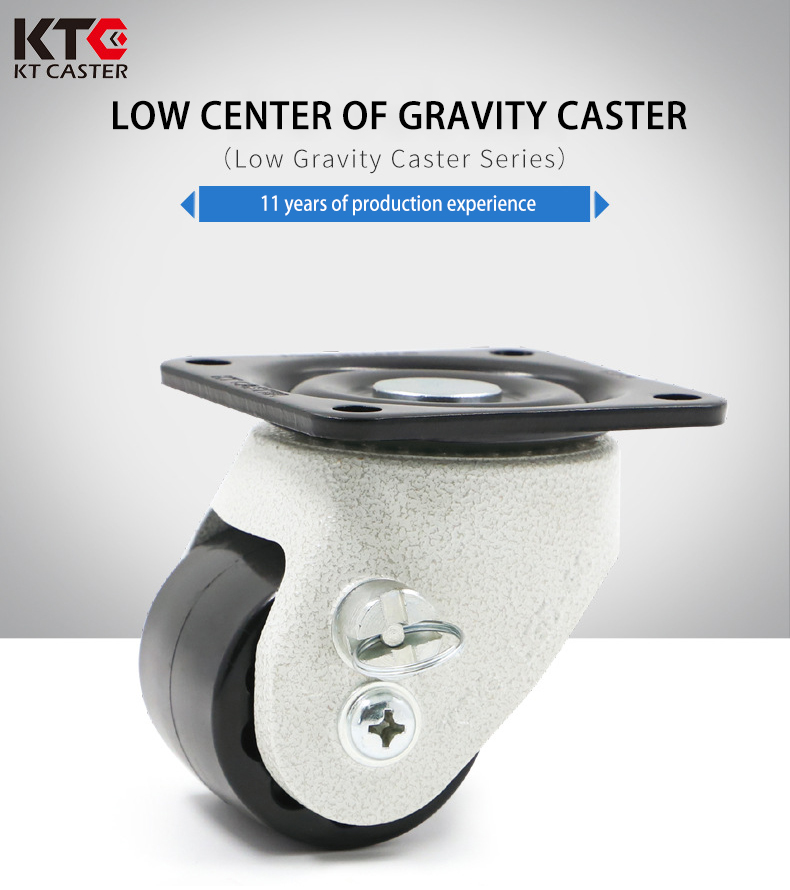

Brand Name : KTCaster

Model Number : KT-LGD-75F

Place of Origin : China

MOQ : 1

Price : USD50-165/Piece

Payment Terms : T/T

Delivery Time : 7 days

Packaging Details : Carton

Certification : RoHs

Applicable Industries : Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works

Warranty : 1 Year

Body material : Steel 45

Wheel material : Nylon6

Type : Heavy Duty caster

Load Capacity : 670kg(EA)

Castor products castor seat treatment quality management

1, Contents and methods of incoming inspection:

1) Visual inspection for appearance: whether there are cracks, bumps and rust spots.

2) Investigate the material of the workpiece: check the way of grinding spark

3) If there is deformation, check the original deformation.

2, Contents and methods of first inspection, intermediate sampling inspection and castor

inspection:

1. Hardness

1) Hardness inspection or sampling inspection shall be carried out according to the drawing

requirements and process regulations. Calibrate the hardness tester with a standard block and test

the hardness after confirmation. Quenched parts shall be inspected with Rockwell hardness tester.

2) Before hardness inspection, the part surface shall be cleaned to remove oxide scale,

decarburization layer and burr, and there shall be no obvious machining marks on the surface. The

temperature of the tested part shall be subject to room temperature, or slightly higher than room

temperature, but only if it can be grasped stably by hands.

3) The hardness testing position shall be determined according to the process documents or by the

inspection and process personnel. The hardness of quenched parts shall not be less than 1 place,

each place shall not be less than 3 points, and the non-uniformity of general hardness value shall

be ≤ HRC 5 degrees.

2. Deformation

1) The flatness of thin plate parts shall be inspected with feeler gauge on the inspection platform.

2) Both ends of shaft parts shall be supported by the center or V-block, and their radial runout

shall be measured with a dial indicator. Small shaft parts can be checked with a feeler gauge on the

platform.

3) For ring parts, use dial gauge, vernier caliper, plug gauge, inner diameter dial gauge, thread plug

gauge, ring gauge, etc. to check the dimensions of the outer circle, inner hole and thread of the parts.

4) Special testing tools for non-standard measured threads and special parts.

3. Appearance: observe the surface with naked eyes for cracks, burns, bumps, pits, corrosion, etc.

Important parts or parts prone to cracks shall be inspected by means of kerosene immersion and

sand blasting.

4. Performance: testing equipment.

3, Inspection contents and methods of permanent deformation of caster base plate:

1. Compress (stretch and twist) the finished caster base plate five times to the height (length or

working limit torsion angle) under the working limit load, and measure the height (or length and

angle) for the fourth and fifth times. If the value remains unchanged, it is considered that there

is no permanent deformation.

2. The inspection of the load and dimensional tolerance, surface shape and position tolerance

of the finished caster base plate shall be carried out after the inspection of permanent deformation,

but the load and dimensional tolerance shall also be qualified before the permanent deformation.

3. Fatigue test, impact test and simulation test of caster base plate: Test of testing equipment.

4. The surface quality of caster base plate shall be measured visually.

Industrial Swivel Casters Parameter

| Wheel material | Nylon6 |

| Load Capacity | 670KG |

| Wheel Diameter | 76mm |

| Color | white |

| Tread Width | 55mm |

| Load Height | 108MM |

Industrial Swivel Casters Describe

Industrial Swivel Casters Size

Industrial Swivel Casters Material

| Name | Material | Treatment | |

| 1 | Caster Seat | Cold-rolled carbon steel | Black Coated/Zn Galvanized |

| 2 | Body | Aluminum alloy | Ivory/Powder Coated |

| 3 | Ball | Bearing Steel | Ni-Cr |

| 4 | Brake | Steel 45 | Zn Galvanized |

| 5 | Pin | Steel 10 | Zn Galvanized |

| 6 | Wheel | PA6 | Black |

Industrial Swivel Casters Scope of application

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007. KTC is a modern

company specialzingin the production of multi function &high quality CASTER and

KT FOOT based on best design and design technology.

The company is headquartered in Niulanshan Industrial Zone,Shunyi District, Beijing. KTC

adopts international advanced production testing equipments, professional intelligent

production management system and professional design flow. Now the company produces

multi function & high quality production, such as KT CASTER and KT FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER, high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level adjusting FOOT

are widely used in the world's advanced automation equipment and semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC use the best processing

technology and equipment. And KTC continuously launches world top level of new products.

KTC's s also has set up a branch in Korea, so it is favored by theusers of various fields around

the world.

| |

|

|

Mechanical Equipment 3 Inch Industrial Swivel Casters 1477lbs Images |